Yeasts are single-celled microscopic fungi that occur naturally throughout nature. There are several species of yeast. The best known is Saccharomyces cerevisiae. Its original name comes from the Latin: “Saccharo” means sugar, “myces” means fungus and “cerevisiae” means “of beer”. Beer was one of the first products in which yeast was identified. However, there are many other genera and species of yeast.

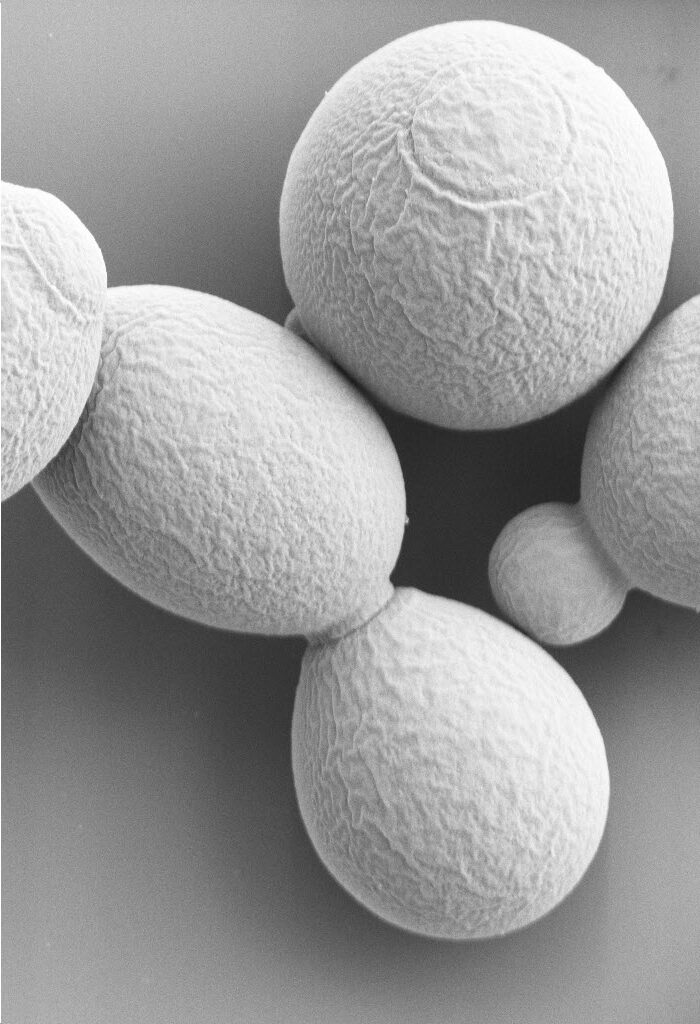

The yeast cell is egg-shaped and can only be seen under a microscope. It measures between 6 and 8 thousandths of a millimetre.

Did you know… A cubic centimetre of yeast weighs about one gram and can contain 10 billion living cells.

Yeast cells multiply by budding: the mother cell produces a bud and splits its nucleus containing its DNA. When it has grown sufficiently, the bud separates, creating a daughter cell. Yeasts multiply very quickly: each mother cell can produce several dozen daughter cells in around two hours.

This process requires specific conditions: adequate temperature, the presence of oxygen (aerobic) and a glucose-rich growing medium to provide the necessary energy.

In industrial production, the growing medium mainly consists of molasses, a co-product of sugar production obtained from sugar beet.

The process is organized in successive stages during which the volume of biomass increases exponentially: in just a few days, from a test tube containing the first mother cells, it is possible to fill tanks containing several tons of daughter cell yeast!

At the end of the process, the yeast is separated from the growing medium that fed it by centrifugation.

This stage allows the recovery of a vinasse co-product rich in proteins and other nutrients, which is used for animal nutrition and potash biofertilizers in agriculture.

The resulting yeast cream is cooled and stored at 4°C so that the cells become dormant. It can then be packaged in different forms adapted to users’ needs: liquid, compressed, dry, etc.

There are many different species and strains of yeast. Some are better suited for baking than for making beer or wine. In wine making, the specific tastes of the terroir are directly related to the strain responsible for fermentation. Today, yeast producers use cutting-edge technology to study and select yeast strains. In the past, selection programmes were based on a few hundred strains, but now they involve several tens of thousands of strains. Modern DNA sequencing techniques make it possible to access yeast genomes within a few days and, using bioinformatics, to decipher their genetic heritage and reveal their unique characteristics.

The European yeast industry relies on vital technical expertise to meet the most stringent requirements. In the food industry, it supplies manufacturers with standardized products with stable fermentation activity, that meet the requirements of industrial manufacturers, artisans and consumers, while also guaranteeing traceability and food safety.

The sector is a global leader and an asset for our continent, serving as:

As early as 3000 BCE, the Egyptians and Babylonians knew how to use fermentation to make leavened bread, but they were unable to explain this mysterious phenomenon.

It was not until the work of Louis Pasteur in 1860 that yeast was identified as the microorganism responsible for alcoholic fermentation. He demonstrated how yeast can live with or without oxygen, multiplying in the former case and fermenting in the latter.